- Compact and space-saving design

- All-purpose application by means of modular design

- Low operating costs

- Optimum treatment of waste waters with high contaminant loads

- Fully automatic working with freely adjustable process flow

- Huge infinitely variable transfer rates

- Optimum adaption for an effective waste water treatment

- No filter fleece for the separation of sludge

- Only liquid treatment agents (chemicals) thus minimum sludge amounts

- Integrated dripping water recirculation

- Trouble-free system expansion and individual adaption by means of accessories on site

- Chemical and physical waste water treatment system for the removal of oil, grease and heavy metals from waste waters

- Energy-saving and user-friendly

automatic design for the treatment of emulsion-charged waste water

Application areas, e.g.:

- Car dealers with parts cleaning

- Grey water treatment

- Effluents from boat washing

- Surface waste water from chip stockyards

- Inside tank cleaning of silo trucks

- Container washing plants

- Cream and skin care products manufacture

- Kitchen waste waters with lipophilic

contents - Cleaning of appliances and motors by means of

HD lances - Soil remediation measures

- For free assembly in rooms – frost-free

- Odour impermeable encapsulated system

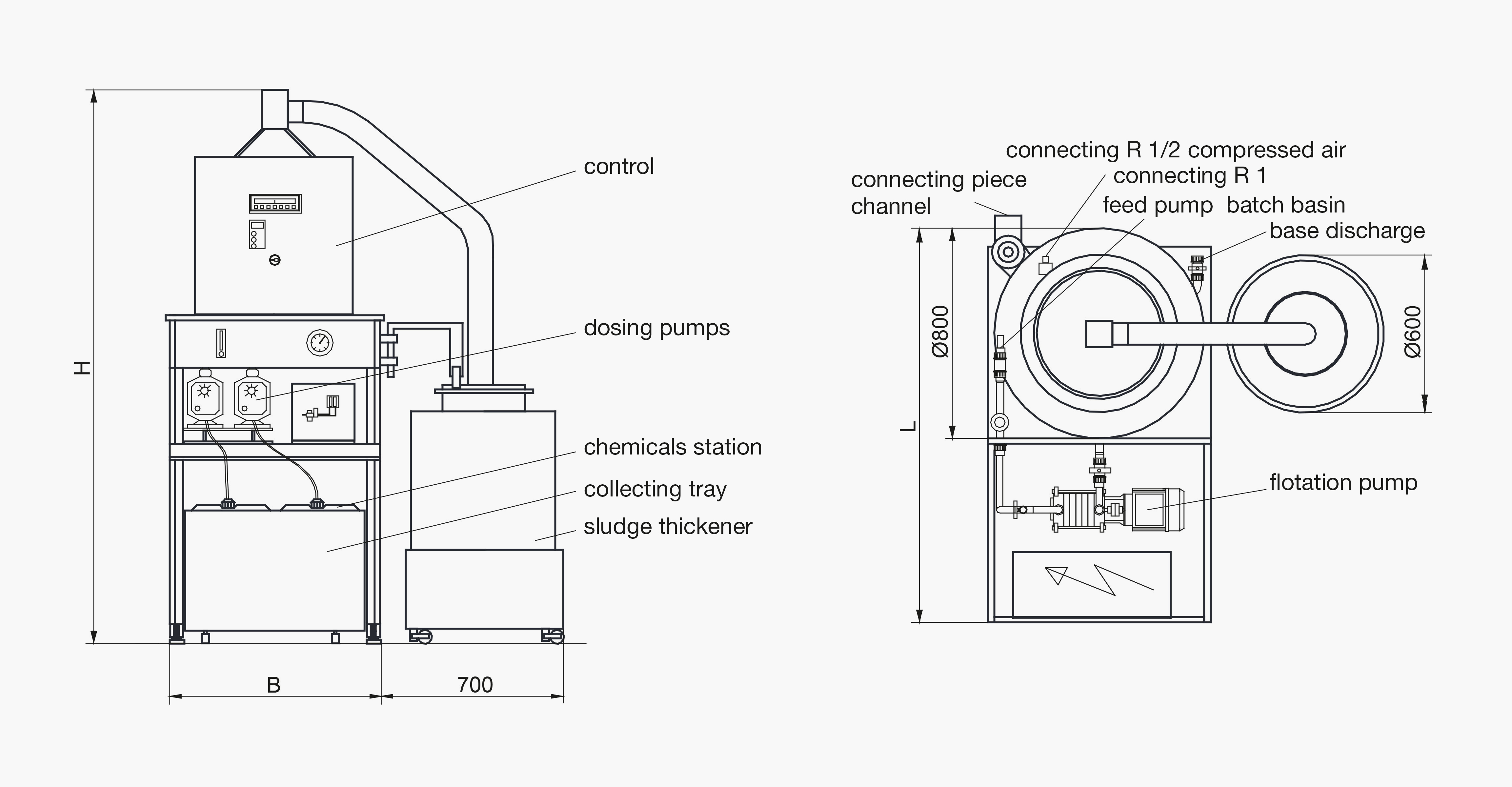

Processor-controlled compact system:

- pH-value measurement and correction for process control

- Feed pump

- Flotation pump

- Static combined system with pressure display, air volume and filling level control

- 3x chemicals dosing pumps for separating agents addition and pH-value correction

- Chemicals container with suction lance and filling level measurement

- Chemicals collection drip pan according to

WHG §19 - Sludge thickener with dehydration sack and integrated dripping water recirculation

- Resources initial fitting out

Control:

- Housing of varnished steel, protection type IP 54

- pH-measuring device with indicator and limit value adjustment

- SPS-controlled operation flow

- Control panel with menu guidance and adjustable times

- Potential-free collecting error message

- Connection possiblity for remote data transfer

- Safeguarding according to the on-site conditions

- Wired ready for connection

protection according to object data sheet - Electric connection

400 V/50 Hz/16 A resp. 32 A

Parameters

| Style | Performance [l/h] | Reaction container content [l] | Weight empty [kg] | Weight filled [kg] | Article-No. |

|---|---|---|---|---|---|

| AtM-Flot 800-D | 800 | 400 | 240 | 650 | 100.00.01 |

| AtM-Flot 1.500-D | 1,500 | 600 | 255 | 860 | 100.00.03 |

| AtM-Flot 2.500-D | 2,500 | 800 | 280 | 1,100 | 100.00.05 |

Further types with other performances are available.

Dimensions

| Style | Dimensions (mm)

L | B | H |

|---|---|---|---|

| AtM-Flot 800-D | 1,400 | 800 | 2,000 |

| AtM-Flot 1.500-D | 1,500 | 850 | 2,100 |

| AtM-Flot 2.500-D | 1,500 | 900 | 2,200 |

Accessories

| Denomination | Description | Article No. |

|---|---|---|

| Dosing pump | For further sewage water treatment. Design with suction device | 100.50.01 |

| pH end control | Optically | 100.50.02 |

| pH end control | Optically with digital recorder | 100.50.03 |

| Sludge thickener | For subsequent dehydration | 100.50.04 |

| Signal module | ■ By remote data transmission (DFÜ ■ Fault indication to mobile phone | 100.50.05 |